AI

AI in Logistics: How Does It Truly Transform The Field?

A few years ago, it would have seemed artificial intelligence would never cover all the complexities of the transportation and logistics industry. However, if there’s one thing that machines are good at even today, it’s helping account for multiple variables; and that’s where AI in logistics has gained a foothold as a respectable factor and player.

In fact, it is estimated that by integrating AI into their processes, logistics companies will generate $1.3 to $2 trillion in economic value each year for the next 20 years, with early adopters enjoying a 5+% profit margin right now.

So… what gives? What exactly does AI offer, and where precisely can it be used effectively? Let's take a look at how it changes the logistics landscape and check out some hands-on examples of how AI is revolutionizing things – from sweetly humming warehouses to delivery routes planned to the second.

AI in logistics: How it impacts the logistics industry?

All of us would love to get into a world where packages know the fastest route to get to us. Can that day arrive immediately, though? However, the transformation of the logistics industry by AI is profound and multifaceted. Once in a world of handwritten/typed lists and manual tasks, with the help of AI, the logistics industry is now transforming into a streamlined machine where everything is predicted in advance with amazing accuracy. A shift from traditional, manual, and time-consuming processes to automated, efficient, and predictive actions can be seen clearly.

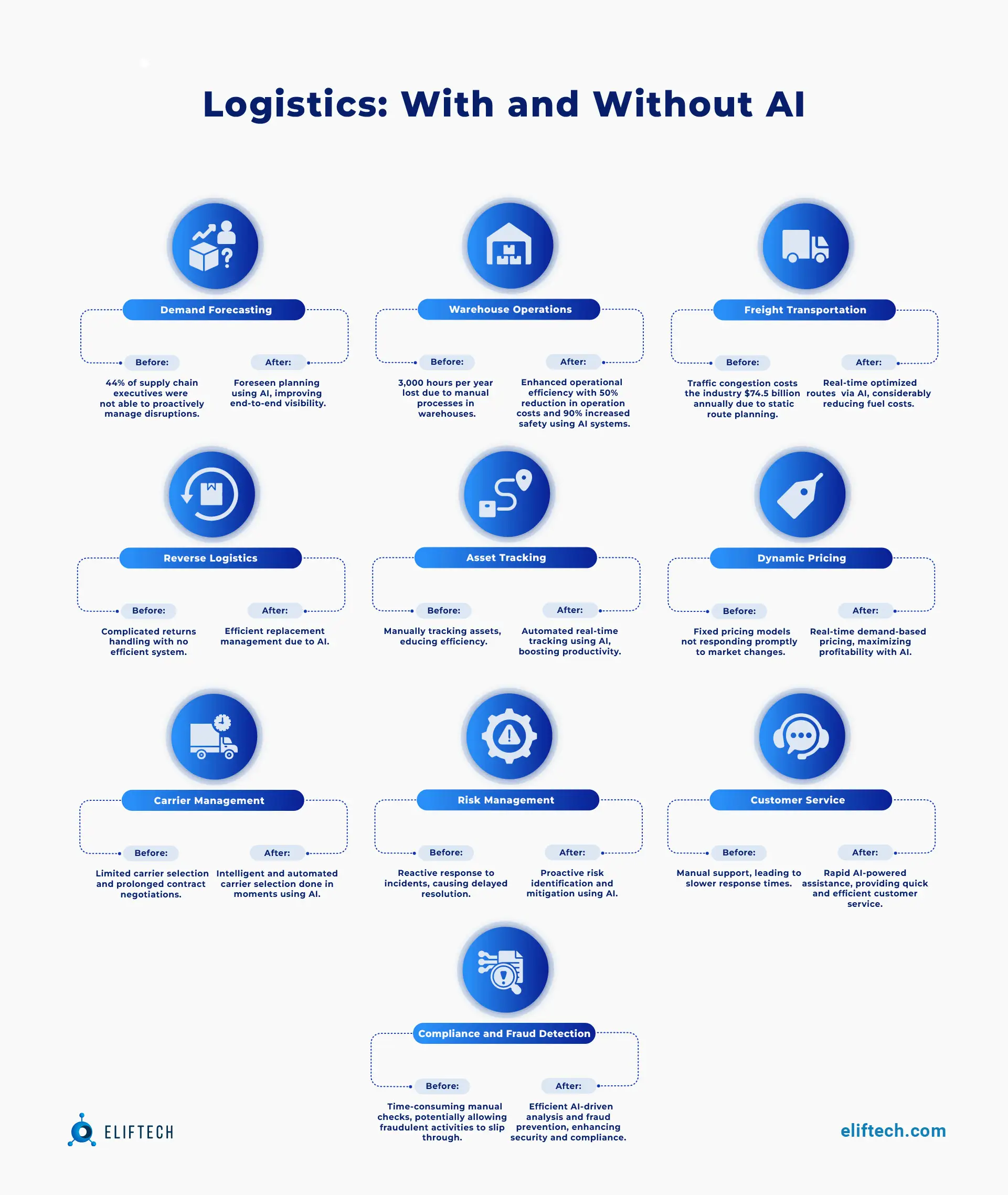

Logistics without AI

Traditionally, logistics has been a complex, manual industry. About 2/3 of typical warehouse operations like picking, packing, and shipping were manually driven. This traditional approach brought about various challenges:

- Problems like unexpected breakdowns and weather conditions can create significant delays in the logistics chain. For example, in 2021, 53% of merchants reported that they experienced package delays.

- Without AI, logistics companies have to rely on manual, static route planning that is unable to adapt to real-time changes in traffic or weather conditions. This can lead to longer transit times and increased fuel costs. In fact, traffic congestion alone costs the industry $74.5 billion annually. (American Transportation Research Institute)

- Managing a supply chain without the predictive capabilities of AI is like sailing in the dark. 44% of supply chain executives prove that they lack the end-to-end visibility necessary to proactively manage disruptions.

- Without automated systems, executing intricate tasks can be time-consuming and error-prone. Warehouses lose approximately 3,000 hours per year due to overdue and manual processes", pointing out the inefficiencies of a manual logistics system.

Logistics with AI

With the advent of AI, the logistics landscape witnessed a significant transition. The Statista report suggests that AI's market value in logistics and supply chains rose to USD 1.3 billion in 2020. Furthermore, statistics highlight that 38% of logistics companies actively employed AI, leading to operating cost reductions of up to 50%.

AI's role in addressing traditional challenges:

- A warehouse with AI can reduce operations costs by 50% while increasing safety by 90%.

- AI enables better handling of potential delays through predictive analysis.

- AI optimizes delivery routes saving valuable time and fuel.

- AI's predictive capabilities prepare for unforeseen disruptions, ensuring better planning.

- AI automates complex tasks, enhancing operational efficiency and accuracy.

In simple terms, introducing AI to logistics has given the industry a total makeover, with experts predicting that by 2035, AI will boost logistics productivity by more than 40%. It's helped solve some of the stubborn problems that slow everything down and has cleared the way for smoother sailing, showing us just how big a difference some smart tech can make.

8 AI use cases in logistics

Now, that we've had a broad look at how AI is transforming the logistics landscape, it's time to focus our lens on specific instances where AI has made remarkable strides. From optimizing warehouse systems to refining delivery routes and predictive analytics, AI is at the forefront of significant advancements. However, understanding the 'how' of these improvements requires taking a closer look at the 'where' they have been applied.

Automated warehousing

A shining example of AI in logistics and supply chain can be found in automated warehousing. AI-powered robots are shouldering functions that were traditionally handled by humans, like sorting and shuttling goods around the warehouse. This cuts back on errors and facilitates optimal space usage. Moreover, machine learning algorithms help adapt the warehouse organization to future needs by predicting patterns of goods' demand. Alongside these, computer vision technology is ensuring heightened precision in tracking, leading to a revolution in inventory management. So, thanks to AI, the warehousing scene in logistics is morphing from a manual, labor-intensive operation into an efficient, technologically advanced process.

Demand forecasting

AI is innovatively revamping demand forecasting in logistics. Unlike traditional methods reliant on historical data, AI incorporates a vast array of variables like weather patterns, regional events, and more using predictive analytics. This results in highly accurate future demand predictions, improving costs, customer satisfaction, and supply chain management. Also, as AI learns from new data, its forecasting precision continually improves, driving demand forecasting from guesswork to data-driven science in logistics.

Predictive maintenance and damage detection

Traditional maintenance schedules, based on time or usage, often fail to prevent unexpected equipment breakdowns. However, AI can help eliminate such issues by spotting potential problems beforehand.

Predictive maintenance uses AI algorithms to analyze data from sensors installed on equipment. This data can identify patterns or anomalies signifying a potential breakdown, enabling preemptive maintenance and reducing unplanned downtime.

On the other hand, AI in transportation and logistics is also enhancing damage detection. Machine learning combined with computer vision can identify and classify damages in delivered goods or assets. This results in quick resolution, minimizing losses, and ensuring better customer satisfaction.

Stock level optimization

AI is revolutionizing stock-level optimization in logistics, a traditionally complex process fraught with overstocks and stock-outs. However, with AI's ability to dynamically adjust and maintain optimal stock levels using predictive analytics, this is changing.

AI systems analyze various data sources, from historical sales data to real-time demand, and precisely predict future stocking requirements. This reduces the instances of surplus inventory and stock-outs, resulting in significant cost savings and improved customer satisfaction.

In essence, with AI, logistics operators can ensure just the right amount of stock at any given time, making logistics operations more efficient and profitable.

Supply chain optimization

AI is playing a crucial role in supply chain optimization, a vital area within logistics and operations management. Traditional supply chain processes are often complex, time-consuming, and vulnerable to human error. However, AI is enabling a more intelligent, efficient, and resilient supply chain.

Several key aspects of AI-driven supply chain optimization include:

- Demand Forecasting: AI uses historical sales data and multiple external factors to accurately predict future demand, reducing stock-outs and overstocks, and minimizing wasted resources.

- Dynamic Route Planning: AI-powered algorithms optimize transportation routes by considering real-time traffic data, fuel consumption, and delivery constraints, resulting in time and cost savings.

- Predictive Maintenance: AI systems analyze equipment sensor data to predict potential breakdowns, enabling proactive maintenance and minimizing downtime.

- Supplier Relationship Management: AI can track supplier performance metrics, identify potential risks, and suggest improvements, fostering better communication and collaboration with suppliers.

Dynamic pricing

AI is changing pricing strategies in logistics through dynamic pricing. Traditional fixed pricing often misses market dynamics, potentially impacting revenue and customer satisfaction. However, AI, by quickly analyzing data like real-time market trends, competitor pricing, and customer purchasing patterns, dynamically adjust prices to optimize sales and profits. Over time, AI's precision in price adjustments improves, ensuring optimal pricing. In essence, AI-powered dynamic pricing boosts both profit margins and customer satisfaction, bringing about a new era of adaptable, intelligent pricing in logistics.

Route optimization

AI is significantly improving route optimization in logistics, which traditionally relies on manual planning and can lead to inefficiency and increased costs. AI employs sophisticated algorithms to analyze various factors, including delivery points, traffic patterns, road conditions, and fuel consumption. Based on this analysis, it generates the most efficient route for deliveries. This not only minimizes travel time and costs but also reduces carbon emissions, proving advantageous for both businesses and the environment. Furthermore, AI systems can adjust routes in real-time in response to changes or disruptions, ensuring that last-mile deliveries are up to today’s standards with documented efficiency gains of up to 30%.

Automating document processing

Last but not least, AI automates the manual and time-consuming process of document processing in logistics. AI-based systems use technologies like Optical Character Recognition (OCR) and Natural Language Processing (NLP) to read, understand, and extract crucial information from physical and digital documents. This facilitates faster data entry, reduces manual errors, and results in significant time and cost savings.

Moreover, AI can manage, organize, and retrieve documents efficiently, thereby streamlining the workflow and significantly improving operational efficiency.

Large companies and startups implementing AI in logistics

AI is now a key component in optimizing logistics and supply chain operations, with many companies harnessing its power to achieve significant efficiencies and cost savings. According to a recent survey, 36% of businesses of different sizes have successfully implemented AI for supply chain and logistics processes, and 28% of survey respondents are on the verge of doing so. Of course, there are headliners in this process, too. Here are several examples of applications of AI in logistics:

Amazon

Amazon, a global e-commerce leader, uses AI to enhance several aspects of its logistics operations. AI-powered algorithms aid in accurate demand forecasting, and optimizing inventory management. Additionally, Amazon uses AI for its automated warehousing systems, where robots pick, pack, and sort items, increasing efficiency and reducing errors. In fact, Amazon is known to utilize about 200,000 robots in its warehouses. Furthermore, Amazon is testing drone deliveries and self-driving trucks, both relying on AI for optimization and safety.

FedEx

FedEx uses AI to automate and improve parcel sorting in its hubs. The AI-enabled robots can sort up to 1,200 parcels per hour, significantly reducing sorting time. Additionally, FedEx uses AI for predictive analytics to forecast potential delivery delays due to weather disruptions or traffic congestion, enhancing their overall customer experience.

Nuro

Nuro is redefining the realm of logistics and last-mile delivery with its AI-powered fully autonomous vehicles. A brainchild of two former Google engineers, Nuro is a pioneer in harnessing AI to reshape the local commerce landscape. By dedicating itself to unmanned deliveries, Nuro leads an environmentally friendly, efficient, and safer transition in logistics, reducing human-driven delivery errors, traffic congestion, and carbon emissions. It's an illustration of how AI can drastically transform traditional logistics models.

ClearMetal

ClearMetal employs powerful AI-driven predictive analytics to tackle the age-old inefficiencies of the shipping industry. With its AI algorithms, ClearMetal can accurately track, predict, and manage the complex dynamics of container logistics. By doing so, it eliminates unnecessary costs linked with mismanaged goods, underutilized shipping containers, and idle assets. Thus, ClearMetal stands as an excellent example of AI's power to turn data into clear, actionable, cost-saving insights in logistics.

GreyOrange

GreyOrange's sophisticated AI-powered robots are perfect case studies for redefining warehouse and fulfillment center operations. Combining robotics with machine learning, GreyOrange's robotics can pick, sort, and pack goods with a high degree of accuracy and speed, far surpassing human capacity. By automating these repetitive tasks, GreyOrange not only slashes human error and accelerates delivery timelines but also frees human operators to focus on more strategic areas. This illustrates how AI makes logistics operations more efficient and smart.

Challenges in AI adoption

Although AI promises significant benefits for the logistics industry, its adoption does not come without challenges. Some of the key obstacles companies face when implementing AI include:

Cost

AI systems can be expensive to purchase, integrate, and maintain. The upfront investment required is still too high for many companies. Acquiring the necessary hardware, software, and expertise requires significant capital expenditure. Smaller firms in particular struggle to get budget approval. However, as AI becomes more ubiquitous, costs are reducing. In reality, AI is one of the factors that help achieve this effect ASAP; according to research, the use of AI in logistics can reduce operating costs by up to 50%.

Integration with legacy systems

Most established logistics companies have legacy IT systems and processes. Integrating sophisticated AI solutions with these can be complex and time-consuming. The level of change required to existing infrastructure is often underestimated. Firms need expertise to map out how AI will work alongside current tools.

Finding the right talent

There is a shortage of staff skilled in areas like machine learning, data science, and AI development. Logistics firms cannot easily recruit the experts needed to implement solutions. Existing employees may lack the capabilities to work alongside AI systems. Extensive retraining and upskilling are usually required.

Managing organizational change

Adopting AI necessitates major changes to operations, roles, and company culture. Having to manage this transition can deter firms from pursuing AI. Employees may be resistant based on misconceptions about AI. Communicating the benefits and providing training helps smooth the path to adoption.

How to understand if your logistics company is ready to utilize AI?

Understanding whether a business is ready to make the leap to incorporate AI into its operations could be a bit challenging. However, the readiness of a logistics company to utilize AI can be determined by the presence of outdated traditional methods and a willingness to transition. Here are the signs:

- The company is consistently dealing with elevated costs due to inefficiencies in the current system.

- There are frequent delays due to inefficient route planning and a lack of real-time data analysis.

- The company struggles to quickly adapt to volatile market conditions.

- Tasks such as picking, packing, and shipping are driven by manual efforts, leading to operational inefficiencies.

- The inability to accurately predict demands and market trends is evident, affecting overall productivity.

What needs to be done next?

Acknowledging these signs catapults the company into the initial steps towards integrating AI. The foremost priority lies in understanding AI's potential to automate tasks, boost efficiency, and curtail costs. Investing in employee training is vital, as it equips team members with the necessary knowledge and skills to successfully navigate the AI landscape.

Also, attention should be paid to upgrading the company's IT infrastructure to accommodate AI technology. This might involve procuring advanced hardware, installing AI-compatible software, and implementing robust data security measures, ensuring a seamless transition as well as optimal performance of the AI systems.

However, the most critical factor in successful AI integration is expertise. This entails assembling a team of professionals, including AI Strategists, AI Engineers, Data Scientists, ML Engineers, and AI Ops Specialists. Each of these experts brings unique skills that help in aligning AI initiatives with business goals, developing tailored AI solutions, managing data, and maintaining AI models in an efficient and effective manner. By securing the right professional expertise, logistics companies can maximize the benefits of AI and achieve a smooth integration into their operations.

What ElifTech can do for you?

Backed by a strong portfolio of successful projects and over a decade of industry-specific knowledge, ElifTech is poised to offer a spectrum of AI-powered and automated solutions for your logistics business. Each custom-built solution is specially fashioned to conquer your distinct challenges and enhance your business workflow.

Our turnkey logistics solutions include proficiently designed Warehousing Management Systems (WMS), Transportation Management Systems (TMS), and Order Management Systems. Further, we facilitate seamless operational workflows with API and third-party integrations and broad system modernization.

Making the best out of AI capabilities, we offer key features that put you one step ahead in the industry:

- Fuel consumption monitoring and analytics

- Dynamic route planning and optimization

- Demand prediction and capacity planning

- Utility monitoring and inventory management

- Predictive maintenance for transportation equipment

We use the power of artificial intelligence to create applications that predict demand, modify orders, automate manual tasks, and save costs for you. Reach out to us to get a consultation and optimize your logistics operations with AI.

Browse our case studies and get actionable insights to drive your success

See more