Logistics

A Full Guide to Automated Inventory Management System

Whether you're running a small business or a whole supply chain for your company you'll know that managing inventory can be a pain. You have to make sure there's enough stock, track what's selling, and monitor the items to see if you're not running low. Additionally, IBM reports that 56% of retail leaders face inaccurate inventory information, affecting their bottom line. What’s even worse, if you set up the wrong amount of inventory because of inadequate inventory management software, you might lose money.

In the past, having an inventory management system was complicated and expensive. Using manual methods for managing inventory stock, your items can easily be damaged or lost. Today, there are automated solutions like inventory management systems that make it easy and affordable for small businesses to take control of their inventory.

In this guide, we will discuss the benefits of an automated inventory management system in reducing errors and keeping you more organized with your product orders.

Costly Mistakes of Poor Inventory Management

Poor inventory management can lead to missed sales opportunities, excess inventory, and other costs associated with carrying too much stock. It also makes it difficult for you to forecast your future revenue and growth because you don't know how much stock you need in your warehouse. According to estimates, poor inventory management costs businesses an average of $1.75 trillion per year.

Missed sales opportunities: If you run out of stock or run low on inventory, this will prevent customers from buying your product or service when they come into the store or contact you online. This means that they might go elsewhere instead, which could cause lost revenue for your business.

Excess inventory: Holding on to excess inventory is another mistake that businesses often make when dealing with their inventory management responsibilities. Keeping too much stock in storage means that you have less room available to store new products when they arrive and also increases the likelihood of damaged items due to lack of space, leading to higher costs

However, it’s worth noting that reportedly businesses with good inventory management practices are 20% more profitable than those with poor practices.

An inventory management system can truly make or break a business. What should a business adopt to ensure it doesn't 'break'?

How Does Automation Transform Inventory Management?

The more complex your business, the more important it is to have an effective inventory management system. Often this is because of the nature of your products or services and the way they are distributed. For example, if you're a manufacturer or wholesaler, you may need to track your inventory at many different locations around the world. In this case, automation is essential if you want to keep track of all those individual items.

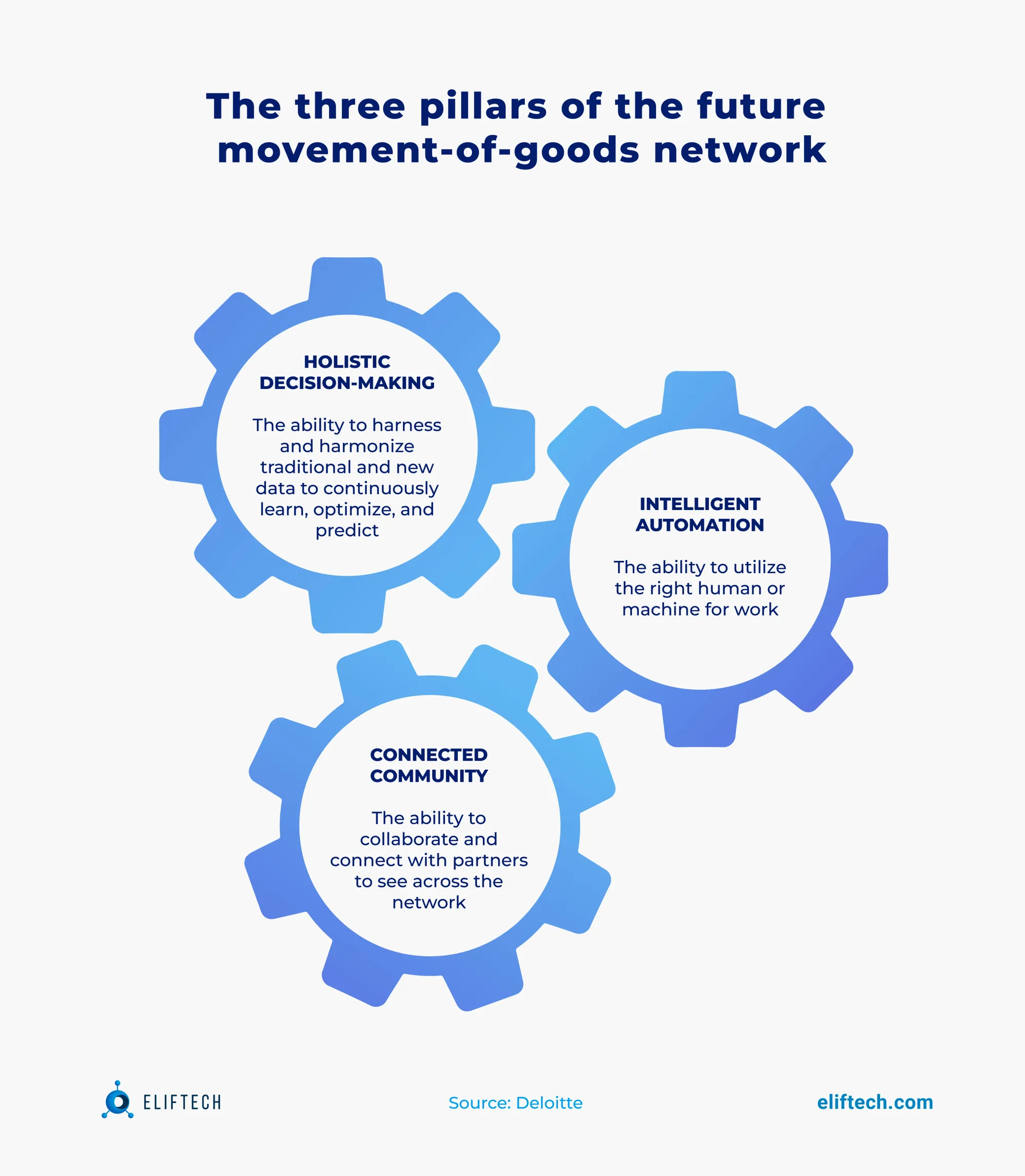

Inventory asset management software can improve the way companies handle their stocks and assets and rely precisely on automation – one of the foundation pillars of a next-generation global movement-of-goods network, along with holistic decision-making and connected community.

How does automation happen?

Automated inventory management uses advanced technology and intelligent algorithms to efficiently control and manage a company's inventory in real time with minimum effort and error. It is intended to simplify procedures, improve accuracy, and give the latest data about inventory levels, demand trends, and supply chain effectiveness.

It works through a combination of 3PL inventory management software, sensors, and data analytics, and involves the following key steps.

Step 1. Data collection. Sensors and connected devices start gathering real-time information on inventory levels, movement, and usage. Then, this data is sent to a centralized system for detailed analysis.

Step 2. Data analysis. Advanced algorithms process the collected data to generate insights. These insights help identify trends, demand patterns, and areas for optimization.

Step 3. Decision-making. Based on the analyzed data, the system can automatically generate alerts, reorder supplies when stock is low, and optimize inventory levels to prevent overstocking or stockouts.

Step 4. Integration. Even inventory management systems for small businesses can also easily link with a wide range of other essential business systems, including point-of-sale (POS) systems that keep track of sales transactions, eCommerce platforms that process online orders, and supplier databases that control incoming shipments. This connectivity allows for real-time data synchronization, accurate inventory updates, and smooth communication between various operational elements of the organization.

Technologies Enabling Inventory Management Automation

The implementation of the 3PL inventory software enables companies to leverage cutting-edge technologies for automating their inventory management functions. Recognizing the potential of these advantages, industry players are making strides in adopting these technologies.

A Deloitte survey on the future of the movement of goods shows these trends. The report reveals that 40% of respondents integrate automated solutions alongside human labor.

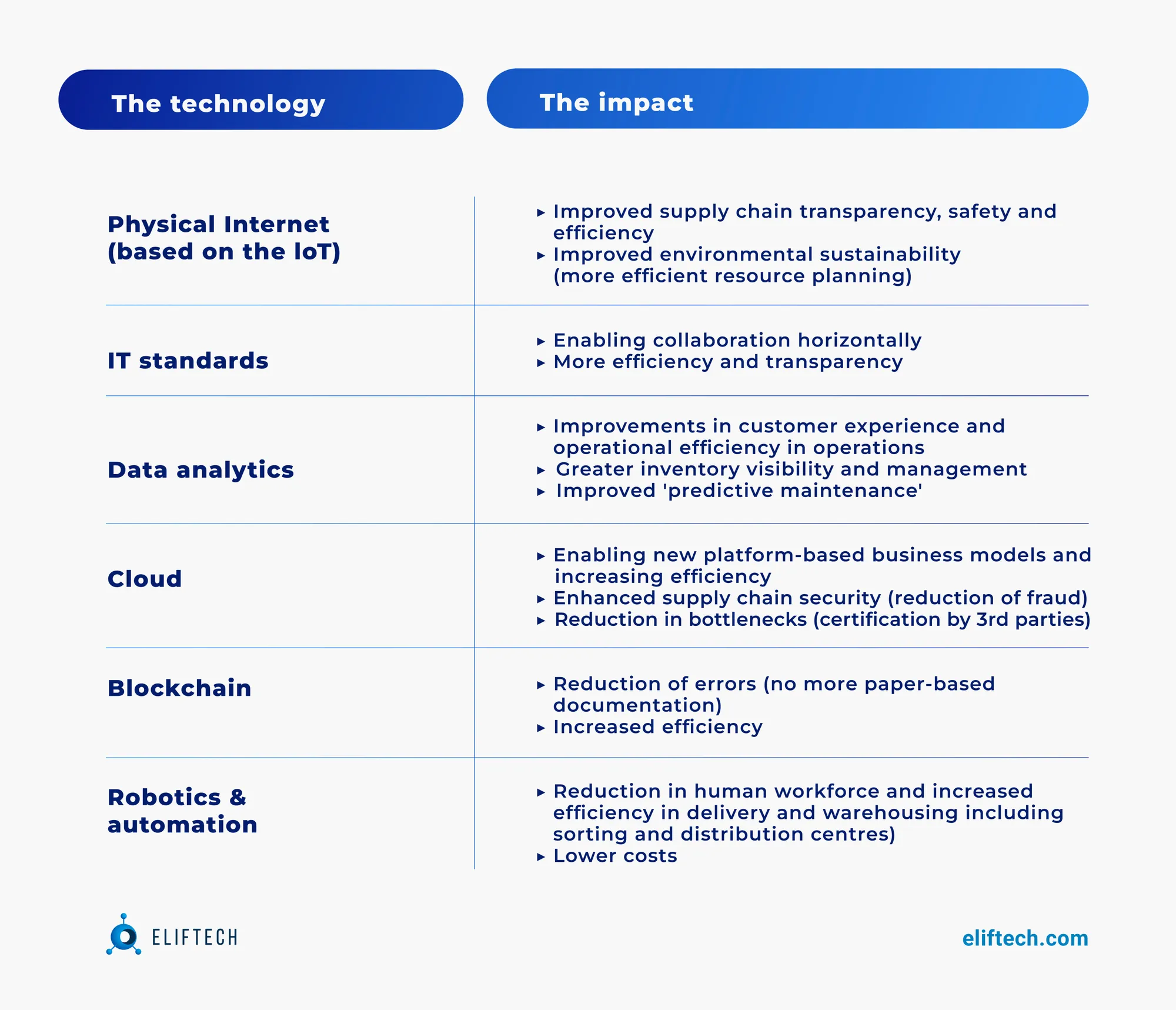

- 37% of businesses also actively use IoT capabilities, while 41% plan to embrace it in the near future. In most cases, retailers use IoT-enabled devices and sensors to track shipments, keep track of inventory levels, and monitor environmental factors like temperature and humidity to ensure excellent product quality during its storage, transportation, and final delivery.

- With cloud computing technology, the situation is almost the same. Cloud-based inventory management systems allow businesses to have a centralized inventory database accessible from anywhere, facilitating real-time collaboration and decision-making.

- Using AI-powered algorithms, 37% of businesses are already analyzing massive volumes of data to spot patterns and forecast demand. As a result, these AI-based systems help them optimize stock levels, reduce carrying costs, and increase supply chain effectiveness – which makes it an attractive investment for the other 42% of businesses.

- Warehouse robotics are leading in adoption by 38% of businesses actively investing in autonomous solutions as well. Employees use automated robotics in warehouses mostly for tasks like picking and packing and transportation of goods, reducing the need for manual labor and improving operational efficiency.

For example, Ocado, a technology company specializing in online grocery solutions for global retailers, has implemented highly automated warehouses that operate 24/7. These advanced facilities enable Ocado to process an impressive 3.5 million items per week, showing the great capabilities of inventory automation in optimizing warehouse operations.

- With blockchain, there is less chance of fraud or error because every transaction is recorded and decentralized. This technology enables real-time visibility into inventory movements, ensures traceability, and enhances supply chain transparency. 35% of organizations have already implemented this technology into their warehouse inventory management systems, and 42% are going to follow the trend.

Areas of Inventory Management under Automation

Inventory asset management software is harnessing the power of intelligent automation to drastically improve operations. This wave of automation is being deployed in several crucial areas:

- Automated reordering: Retailers often use this to maintain optimal stock levels.

- Stock transfer tracking: Ensures accurate inventory records by tracking stock transfers within a retail chain.

- Consolidated reporting: Offers a comprehensive view of inventory levels, sales performance, and other key metrics from multiple locations.

- Store orders handling and notifications: Automated systems efficiently handle store orders and dispatch notifications.

All of these automation options collectively help businesses streamline their operations, reduce manual intervention, minimize errors and costs, and enhance accuracy. These benefits ultimately lead to greater operational efficiency, a critical key performance metric for companies looking to respond effectively to the dynamic demands of modern business landscapes and remain competitive.

Types of Automated Inventory Management Solutions

You've got a lot of options when it comes to automated inventory management systems. Depending on your business needs and requirements, you may want to consider one of the following types of solutions:

Barcode inventory management system and RFID systems

A barcode system for inventory management is a very basic solution that can work for small businesses or even individuals who want to keep track of their inventory. It's not uncommon to see this setup at craft fairs or garage sales where people have multiple tables and items spread out over a wide area. RFID systems take this a step further with radio-frequency identification tags that communicate wirelessly. RFID allows for real-time tracking and faster inventory checks without the need for manual scanning, leading to more accurate results.

Recommended article: How Using Your Phone for Mobile Barcode Scanning Drives Greater Accuracy in Logistics

Point of sale (POS) systems with inventory management

Through the integration of POS systems with inventory management, every transaction has an immediate impact on inventory levels. It alerts when stocks are low and triggers automatic reorder requests. By reducing the likelihood of out-of-stock situations, businesses can better control inventory movement, resulting in timely replenishment.

Inventory control software

Software for inventory management systems goes beyond simple tracking. It has a wide range of features, including the capacity to calculate demand based on previous data and the state of the market. Also, modern systems take seasonality and trends into account to help with more informed replenishment decisions. As a result, real-time reports show which items are moving slowly or have too much stock, making it easier to manage and rotate stock effectively.

Recommended article: A Full Guide to Automated Inventory Management System

Supply chain management systems

These are larger systems able to perform several inventory-critical tasks. Such a consolidated platform can include capabilities to forecast and plan demand, optimize routes, control inventory levels, track shipments, collaborate with suppliers, and more. Their core mission is to bring greater visibility across the entire supply chain, from suppliers to end customers. When integrated with inventory management, they offer a complete view of inventory movements. This helps coordinate production, reduces delays, and allows businesses to respond quickly to changes in demand or supply issues. By using these systems, businesses can operate more efficiently, save costs, and meet customer requirements on time and with quality.

Just-in-time inventory systems

Just-in-time (JIT) inventory systems are based on a JIT strategy aiming to reduce inventory costs and prevent excess inventory storage. Businesses order goods only as they are needed for production or sales. However, implementing JIT requires precise demand forecasting, reliable suppliers, and efficient logistics to ensure timely deliveries.

Demand forecasting software

Advanced technology like machine learning algorithms, artificial intelligence (AI), and data analytics tools help businesses anticipate future demand by utilizing statistical models, historical sales data, and current market trends. In simple words, demand forecasting software helps businesses manage their inventory better, save costs, and ensure they don't run out of products when customers want them.

Mobile inventory management apps

Mobile apps function like smart pocket-size assistants providing quick access to inventory data. Staff can use smartphones or tablets to perform inventory counts, track movements, and even receive alerts about low stock levels. Mobile applications are often seen as the logical next step after developing a web-based inventory management system, as they increase flexibility and reduce manual data entry, greatly accelerating corporate growth.

Internet of Things (IoT)-enabled solutions

Sensors are IoT-enabled devices used to monitor inventory conditions in real time. For example, temperature sensors ensure that perishable products are kept in the right conditions. This technology prevents spoilage, helps maintain product quality, and can trigger alerts if conditions deviate from acceptable ranges.

Functions Inventory Management Systems Should Support

3PL inventory management systems deliver a range of essential functions to help businesses maintain precise inventory levels, optimize costs, and ensure timely availability of products. While these systems vary extensively based on their offered functionalities, most of them have several common functions.

Functions Inventory Management MUST Support

Component 1. Order management

This component handles the entire order lifecycle, from creation to distribution. This includes order processing, tracking, and management of shipping and delivery. It accurately processes and delivers customer orders on time, enhancing their satisfaction.

Component 2. Product tracking

When you have many products stored in one or several warehouses, it's important to track them all from a single location. This makes it easy to see which products you need and helps you make smart choices about restocking and sales.

Component 3. Barcode scanners and RFID tags

Barcode systems for inventory management and RFID tags play a decisive role in speeding up the inventory management process. Using them, you only need to scan items upon their arrival in the warehouse, and the ERP system will then automatically update the stock levels.

Component 4. Replenishment planning

This component figures out the best time to order more products and how much to get. It considers factors like past sales, the time it takes to restock, and the amount you want to keep. This ensures you don't run out of items and also prevents overstocking and corresponding excessive carrying costs.

Component 5. Forecasting and demand planning

The capability to integrate with demand forecasting tools is particularly valuable to define the appropriate order quantities for each product based on past sales data.

You should consider having these plugged

Component 6. Reporting and analytics

Data analytics and reporting modules are crucial aspects of efficient inventory management that are sometimes underestimated. Generated data and comprehensive reports on inventory performance, trends, and key metrics play a huge role in effective decision-making.

Component 7. Integration with other systems (e.g., POS, ERP, CRM)

Implementing intelligent automation allows you to integrate your preferred tools to manage all business operations, consolidating your entire business into a single platform. Inventory management system software may integrate with POS systems for seamless sales tracking, ERP systems for streamlined resource planning, eCommerce platforms for efficient online sales management, CRM systems for enhanced customer interaction, accounting apps for accurate financial tracking, and more.

Component 8. User access control

Consider the scale of your business when selecting software; it might need to accommodate multiple users. Even if not currently essential, this feature could become crucial as your business grows.

Component 9. Mobile support

With mobile support, businesses can manage their inventory data from anywhere on the go. Your 3PL software solutions can offer mobile websites or dashboards that work on phones, tablets, and other mobile devices.

Component 10. Supplier management

By automating communication processes, businesses may improve collaboration and lower the chance of miscommunication. This element makes certain that the flow of items continues to be constant, allowing quick replenishment of inventory levels. Additionally, it gives companies the ability to monitor supplier performance, measure delivery schedules, and assess the quality of items they get.

What to look for while choosing a warehouse management system?

There are several critical considerations to make when deciding which inventory management system is best for your company. By weighing these elements, you can make an informed decision that suits your unique needs and preferences:

- Integration capabilities. Give top priority to a system that easily connects with your existing hardware and applications. For instance, ensure it can communicate with your e-commerce platforms, ERP software, and Point of Sale (POS) system. It's crucial to take this aspect into account beforehand to prevent potential disruptions during implementation and to ensure accurate data exchange.

- Scalability. Keep the future in mind. Look for a solution that can grow alongside your business. If you have plans to expand your product offerings, open new locations, or tap into different sales channels, a scalable system is vital to accommodate these needs.

- Budget. Be transparent about your budget. Besides the upfront costs, consider ongoing expenses like maintenance, updates, and potential training sessions. Balancing cost and features is essential to ensure you get the most value within your financial limits.

- Technical support. Evaluate the quality of technical support offered by the system vendor. Fast and reliable help with troubleshooting or inquiries can go a long way in keeping you up and running.

- Design specifics. Advocate for a user-friendly interface. The system should be simple to use and easy to understand, enabling your employees to quickly become familiar with its features. While some training might still be necessary, you can at least ensure the design acts as a clear and understandable “how-to-use” guide. Check more details about our design offerings.

- Customization. Every business operates differently. Seek out a system that can be customized to suit your specific needs. This could range from adjusting report formats to adapting workflows to match your existing processes.

- Security measures. Given the sensitive nature of inventory and business data, prioritize a system with robust security measures. Ensure the development team uses data encryption and ongoing security updates.

The factors mentioned above will guide you in determining the key priorities for the development of inventory asset management software or, at the very least, in choosing the appropriate development option, whether that's a custom solution or a ready-made one.

Rewards of Having Your Inventory Management Automated

As businesses become more involved in digitalization to enhance the potential of their inventories, they begin to realize the advantages that automation can offer.

Streamlined Replenishment and Purchase Orders

Automated inventory management systems can analyze inventory levels, track sales data, and even generate accurate forecasts. For instance, the system automatically creates purchase orders and allocates them to vendors when inventory falls below a predefined threshold. This approach ensures that businesses maintain optimal stock levels and reduces the likelihood of stockouts or overstocking.

Efficient Delivery Management

Automated systems track incoming shipments in real time. With this feature, companies can accurately predict delivery schedules, monitor the status of orders, and address any potential delays immediately. As a result, effective delivery management greatly improves customer satisfaction by ensuring that orders are delivered on time.

Automated Fulfillment Assignments

When an order is received, an automated inventory management system selects the best-suited warehouse or location to fulfill the order. It takes into account things like proximity to the customer, stock availability, and transportation costs. This automated distribution shortens shipping routes, improves order fulfillment, and eventually speeds up delivery.

Holistic Inventory Tracking

Thanks to automated inventory management, businesses may view their inventory in real-time across many locations, such as warehouses, retail stores, and online marketplaces. This real-time visibility helps businesses make informed decisions regarding stock distribution, allocation, and reordering. It also minimizes the chances of underutilized or overburdened inventory.

Synchronized Sales & Inventory Data

Automated systems can integrate data with inventory levels, point-of-sale (POS) systems, and other sales channels. This synchronization of sales and inventory data enables businesses to track product demand trends, identify popular products, and forecast future inventory needs. In turn, informed restocking decisions based on real-time sales data prevent both stockouts and overstocking, and help businesses change prices, run promotions, and restock.

Effective Omni-Channel Inventory Management

In light of the growth of omnichannel commerce, businesses need to effectively manage inventory across various sales channels, including physical stores, online marketplaces, and social media platforms. Automated inventory systems provide a unified view of inventory across all these channels. They function as centralized platforms, enabling seamless inventory management, optimizing stock allocation, preventing overselling, and ensuring a consistent customer experience throughout.

What ElifTech brings to your inventory management

With all the benefits and transformative effects of transitioning from manual to automated inventory management systems, it's clear that this move is a vital driver for business growth and increased efficiency. To make this leap better for you ElifTech offers a comprehensive suite of warehouse and inventory management solutions.

- Inventory visibility & tracking: Gain real-time insights into your inventory, ensuring seamless operations and preventing stockouts.

- Product volume management: Track stock levels promptly while maintaining optimal product volume in the warehouse, reducing waste, and maximizing profitability.

- Warehouse reporting: Stay informed with customized dashboards and insightful analytics to enhance decision-making and streamline warehouse processes.

Transform your warehouse operations with ElifTech's solutions. Experience unparalleled efficiency in inventory management and reporting. Get in touch to request a consultation.

Browse our case studies and get actionable insights to drive your success

See more